Insights

Choosing the Right Cutters for Electronics Manufacturing

When it comes to electronics manufacturing, the tools we use can make all the difference. Cutters, whether they’re high-end precision tools or more budget-friendly stamped versions, are essential for tasks like trimming leads, cutting wires, and making fine adjustments.

Metcal’s Connection Validation™ System Revolutionizes Soldering Training

With the national shortage of soldering technicians and operators, getting new employees trained quickly has become a challenge for the electronics industry.

Choosing the Right ESD Chair

Humans encounter the nuisances of static electricity in their daily lives, from the unexpected jolt when shuffling across a carpet to the potential hazards it poses in workplaces with high electrical activity. In industries such as semiconductor manufacturing, automotive, and medical fields, Electrostatic Discharge (ESD) can wreak havoc on delicate electronics, leading to costly repairs and decreased productivity. Incorporating ESD-safe furniture, including chairs, is a crucial step in mitigating these risks and maintaining operational efficiency.

How to Configure Your Electronics Lab Workbench

If your company assembles or makes electronics, choosing the right workbench design is key for your production area. Missing a key design component can leave you scrambling. You'll need to fix the issue it may cause in your production.

How to Use a Custom ESD Solution to Quickly Increase Efficiency: A Case Study

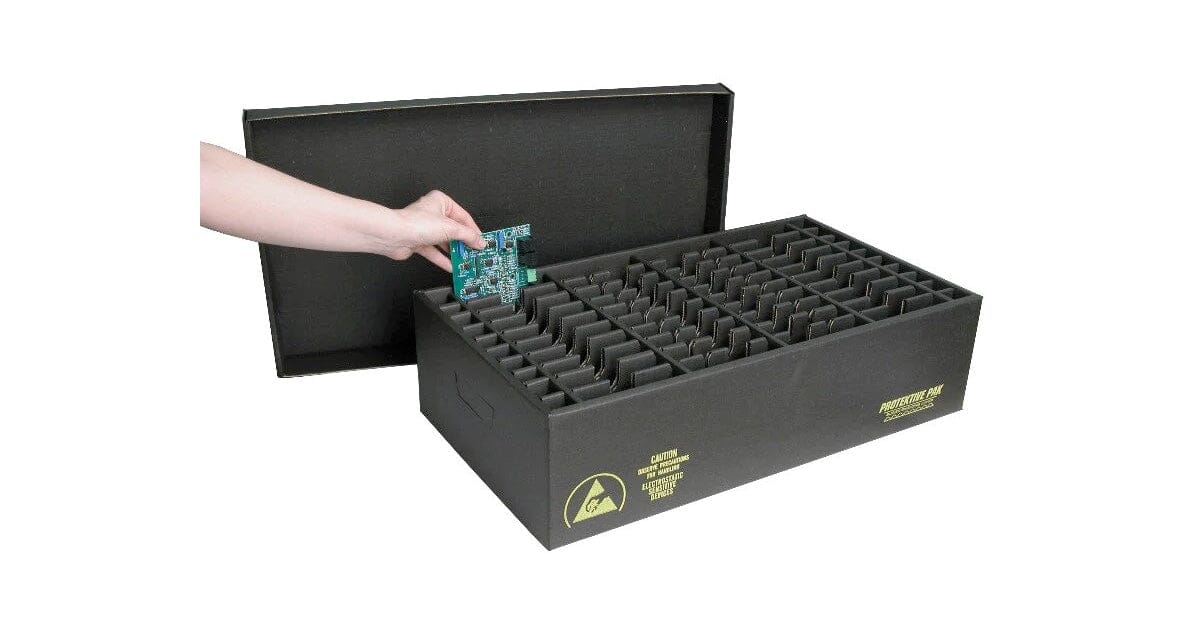

A local military and aerospace manufacturer was challenged with finding an ESD tray to meet specific requirements to handle their components from receiving/storage to production. Their Manager of Logistics and Inventory Control was responsible for organizing the BOM for their customers as they received parts to store in the warehouse and move to the floor. They needed a way to receive, organize, and move ESD sensitive components from inventory to production.

Understanding the Fluctuating Price of Solder: Unveiling the Factors at Play

Solder, a crucial component in electronics and various industries, is subject to price fluctuations that can impact manufacturers, hobbyists, and consumers alike. In this article, we will delve into the reasons behind the fluctuating price of solder, shedding light on the key factors that contribute to these variations. By gaining a deeper understanding of these factors, we can better comprehend the dynamics of the solder market and make informed decisions.

When Custom ESD Solutions Make Sense: A Case Study

One of SMT Supplies’ customers was facing a specific challenge with one of their new products, which required a specific in-process production function. They needed to move critical items that were susceptible to ESD (static) sensitivity from receiving into and through production, but they were unable to find a good solution for this. They tried many different options, including building their own wood containers. However, none of these solutions were successful.

Microscopy in the Electronics Manufacturing Industry: The Differences between Binocular, Trinocular, Digital and Hybrid Systems

In the realm of electronics manufacturing, where precision and attention to detail are paramount, the tools we employ can determine the difference between a flawless product and costly rework. In this high-tech landscape, binocular and trinocular microscopes, alongside the ever-evolving realm of digital and hybrid systems, have emerged as essential assets. These instruments are at the heart of a quality assurance program that scrutinizes the intricate world of Printed Circuit Boards (PCBs) and electronic components.

Safeguarding Electronics: The Crucial Role of Electrostatic Discharge Safe Racks and Trays

In today's interconnected world, electronics play an indispensable role in our lives. From smartphones and laptops to complex industrial machinery, these devices drive innovation and efficiency across industries. However, the rapid advancement in technology has brought about an equally critical concern – the vulnerability of sensitive electronic components to Electrostatic Discharge (ESD). To mitigate the risks posed by ESD, the electronics industry relies heavily on electrostatic discharge safe racks and trays. In this article, we delve into the importance of these essential tools and how they help ensure the integrity and reliability of electronic components.

How to Choose the Right ESD Rack and Tray for Your PCB Components

One of the main challenges of any PCB manufacturing company is to increase yields and one of the commonly overlooked areas is the ESD transportation method. It can be frustrating to have the boards successfully go through the entire manufacturing process just for there to be mishandling of the finished product at the end of the line, resulting in lower production yields.

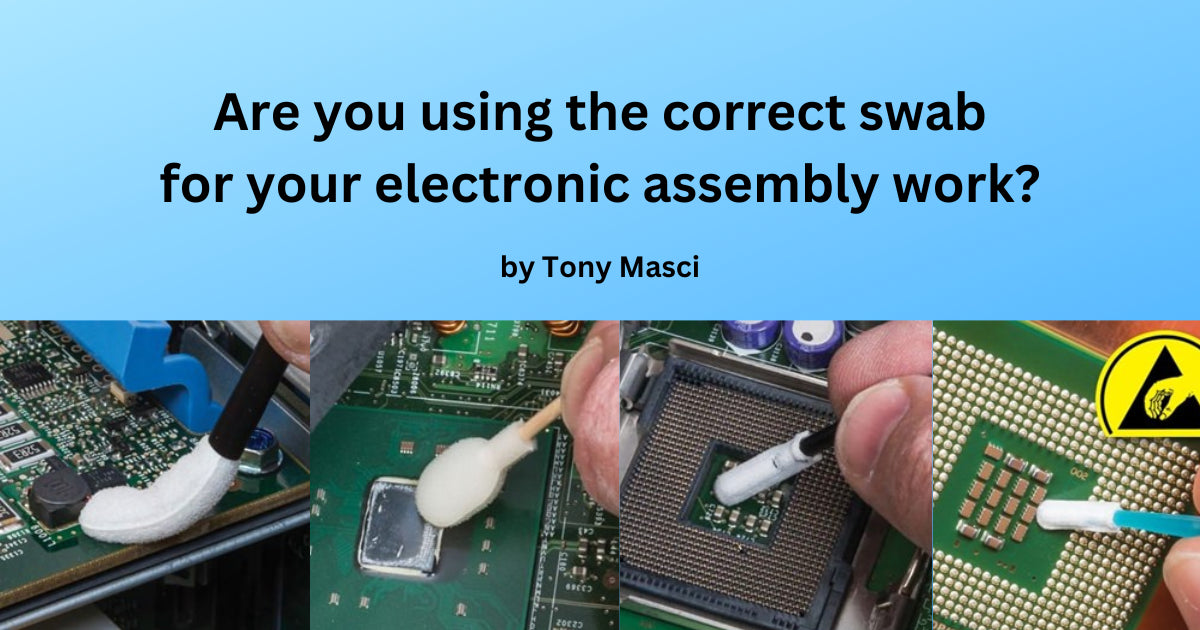

Are you using the correct swab for your electronic assembly work?

Swabs have come a long way since the simple cotton swab on a wood stick was the norm. And while cotton swabs have their uses, more complex solutions are needed for critical industries like laboratories, medical device assembly, cleanrooms, electronic manufacturing, PCB assembly, and rework and repair.

How to Choose the Right Magnifying Lamp for Use in the Electronics Industry

In the electronics industry, precision and attention to detail are crucial. Whether you're an electronics hobbyist, technician, or professional, having the right tools is essential for accurate and efficient work. One such tool that plays a significant role in enhancing visibility and precision is a magnifying lamp. In this blog post, we will guide you through the process of choosing the right magnifying lamp for your specific needs in the electronics industry.