Insights

Why Water-Soluble Flux Is More Popular in California's Electronics Manufacturing Industry

While no-clean fluxes dominate in some regions due to their convenience and lower cleaning requirements, California's electronics manufacturers continue to rely heavily on water-soluble alternatives. So why the difference?

When to Use a Pre-Heater and/or a Hot Air Station Instead of a Traditional Soldering Station

While traditional soldering stations remain essential tools for most assembly and repair tasks, there are situations where a pre-heater or hot air rework station is a more effective solution. Understanding when to reach for one of these alternatives can greatly improve your process, product quality, and component longevity.

Choosing the Right Ionizer for Your ESD Environment (Part 2)

In Part 1 of our ionization series, we explored when ionizers become essential in your ESD protection strategy. Now let's dive into the different types of ionizers available and how to select the best solution for your specific manufacturing environment.

When Should I Use an Ionizer in My ESD Safe Environment? (Part 1)

Electrostatic Discharge (ESD) represents a silent but potentially devastating threat to electronics manufacturing operations. While many facilities implement fundamental ESD control measures, such as grounding wristbands, ESD mats, and specialized footwear, there are situations where these standard practices are insufficient. That's where ionization technology comes into play.

How to Choose the Right Lead-Free Solder for Your Application

While the transition from traditional tin-lead solder to lead-free alternatives is largely driven by regulations such as RoHS (Restriction of Hazardous Substances), it also introduces a new set of considerations when selecting the right alloy for your process.

Flux Removers and Degreasers: Effective Solutions for Electronics and Industrial Use

Flux and grease residues can have detrimental effects on both electronic assemblies and industrial equipment. In electronics, flux residues left from soldering can cause corrosion, short circuits, and performance degradation. Meanwhile, industrial environments often face the challenge of heavy oils, grease, and grime accumulation that can compromise machinery efficiency.

How to Remove Solder From a Printed Circuit Board

Whether fixing a faulty connection, replacing a component, or salvaging parts from an old PCB (Printed Circuit Board), knowing how to remove solder properly can make the process smooth and efficient.

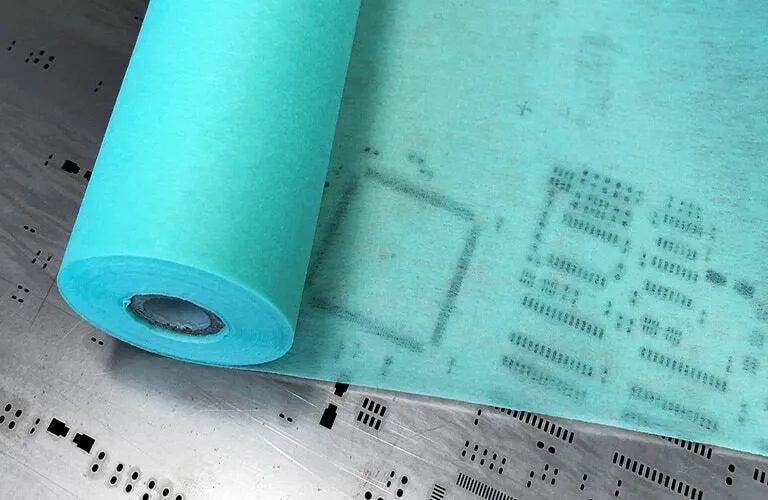

Choosing the Right Under Stencil Wiping Roll for Your SMT Process

As a distributor serving the electronics manufacturing industry, SMT Supplies understands that high-quality under-stencil wiping rolls are essential for achieving reliable solder paste printing in your SMT process. The right wiping roll can help reduce defects such as smearing, bridging, and solder balling, ensuring a cleaner and more efficient production line.

When to Use Low-Temperature Soldering

Low-temperature soldering has become an essential process in modern electronics manufacturing, offering unique advantages for specific applications. But when should you consider using low-temperature soldering over traditional soldering methods?

Protecting ESD and Moisture-Sensitive Devices During Storage and Transportation

Explore the best practices for safeguarding ESD and moisture sensitive devices during storage and transportation

The Role of Fume Extraction Equipment in Wave Soldering

Wave soldering remains a cornerstone process in electronics manufacturing, enabling reliable solder joints for high-volume circuit board assembly. However, the process generates significant fumes containing harmful substances such as flux residues, particulate matter, and volatile organic compounds (VOCs). This is where fume extraction equipment becomes a game-changer, ensuring a safer working environment and better production outcomes.

How To Prevent Conformal Coating Defects

Whether you’re just starting to explore conformal coatings or looking to improve your existing processes, here are some tried-and-true strategies we’ve gathered from the field.